We have a challenge.

The greatest challenge in the history of humanity.

There is a world to save. Which means that each and every one of us must

rethink, reprogram ourselves and change the way that we usually do

things. The construction industry in the UK alone makes up 40 percent of

the total CO2 emission numbers. The king of wasteful thinking, really.

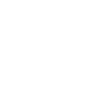

By 2030 we must reduce the CO2 footprint from 1000 kg/ m2 down to 300 kg/m2 to reach a carbon neutral target. That's steep, but not impossible. And above all, necessary. At NorDan

we are happy to be the forerunners in the transition to a sustainable construction industry. Of course, we try to lead by example - we've done if for nearly 100 years.

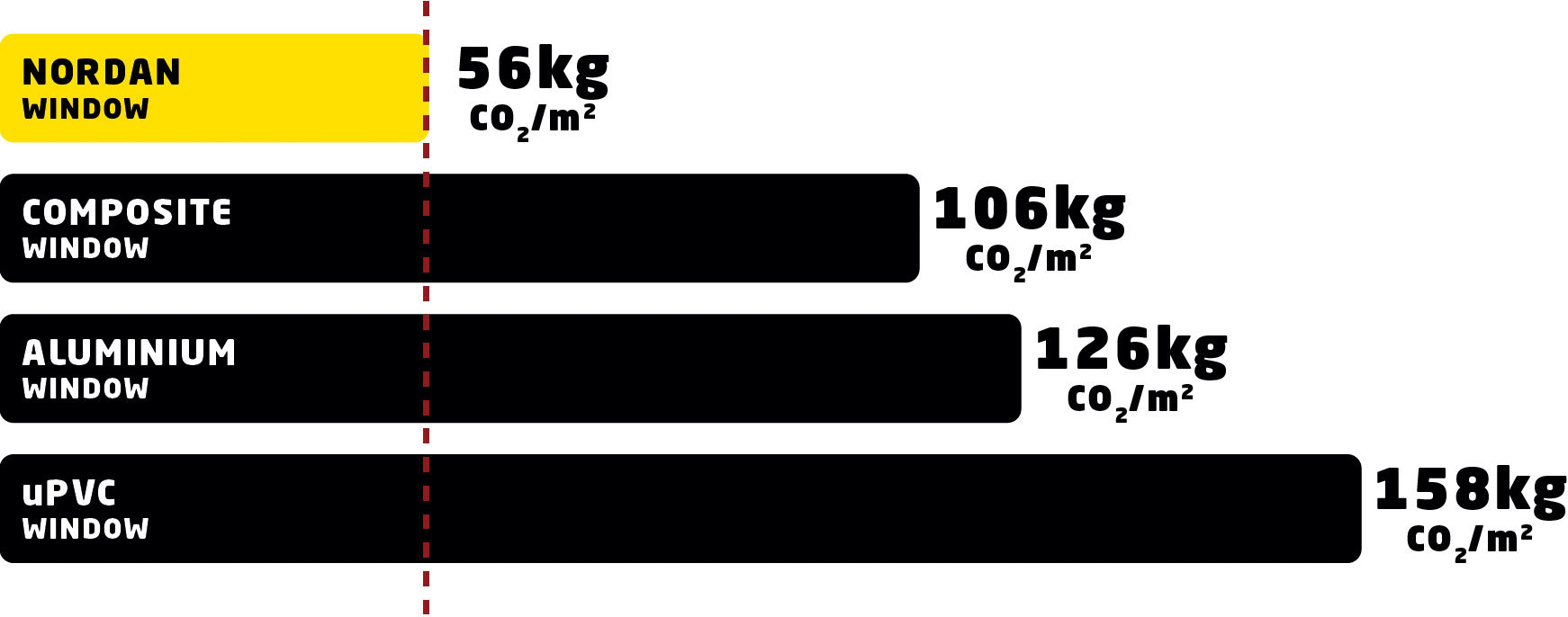

An ordinary NorDan window frame is made from more than 90% timber, a natural carbon sink in itself. With timber at the core, our embodied carbon figures are among the lowest industry. With embodied carbon emissions from NorDan less than half compared to aluminium or uPVC. Even against other composite materials in the market, there is no comparison.

Embodied Carbon – EPD Analysis

We've done it for nearly 100 years.

Since the founding in 1926 both the company and larger society has gone through significant changes, but one thing remains the same: NorDan is a family owned company, and is run by the same basic values as when founded.

The group’s head office is in Moi in Norway, the exact same place the company was founded almost 100 years ago. NorDan is present in Norway, Sweden, Denmark, United Kingdom, Ireland, Poland and Lithuania. Today NorDan consists of 12 factories, approx 30 project management offices and more than 2200 employees.

We are a network of offices, factories and competence centres all interconnected by thousands of employees who share our common values towards a sustainable future.

COP26: NorDan Products Featured in Zero Carbon House Project

We are delighted to announce that NorDan UK is involved in the COP26 House project, developed to showcase zero carbon construction and living during the COP26 event in Glasgow this November.

NorDan will be be working with collaborative group Beyond Zero Homes, which through a partnership with several businesses, will be building and showcasing the zero carbon, timber frame COP26 House.

Designed by Peter Smith, of Roderick James Architects, the COP26 House is being built close to the conference site . Its structure is entirely made of timber – including the roof – in order to harness the unrivalled carbon sequestration and additional wide-ranging benefits of wood for environmental and human health.

NorDan is with Beyond Zero Homes to deliver the finished product, providing a range of aluminium-clad timber windows and doors including HomeGuard entrance doors. We were selected as a supply partner for the project due to the excellent low embodied carbon credentials of our timber-cored products, combined with their efficient operational carbon qualities.

The combination of NorDan products’ outstanding low carbon credentials, long life expectancy and ultra-low maintenance requirements that aluminium-clad timber brings means that the low whole life costs make the product ideal for many projects and clients.

We are proud and excited to be involved with this project and there is truly no better showcase for the possibilities of zero-carbon living and the ease of which such buildings can be produced.

High Performance

EMBODIED CARBON

› NorDan StormGuard - 56kg co2/m2

› Composite window - 106kg co2/m2

› uPVC window - 158kg co2/m2

› Aluminium window - 126kg co2/m2

OPERATIONAL CARBON

› NorDan double glazed unit: 1.2 u-value

› NorDan triple glazed unit: 0.9 u-value

› NorDan Passive unit: 0.7 u-value

AIR PERMEABILITY

› Standard Inward & Outward opening windows:

0.1m3/m2h at 50Pa

ACOUSTIC PERFORMANCE

› Double glazed unit: 44dB Rw

› Triple glazed unit: 45dB Rw

› SoundGuard unit: 60dB Rw

State-of-the-art durability

What makes the durability of our windows so superior is the fact that our aluminium is treated with a FOX Fast Oxidization Process, which is a rapid anodic oxidization treatment that deposits a layer of oxide on the surface of the aluminium. The process creates billions of microscopic pores that when the powder coating process is completed, the pores are filled with powder and grips onto the aluminium, creating a much tougher finish for the material.

Not only does this protect the timber frame, but it also provides marine grade resistance against sea air and salt water. NorDan are proud to hold GSB Sea Proof Plus certification which is made possible via our state-of-the-art factories. This certification and our process also ensures our products are suitable for areas with high levels of pollution in the air. NorDan aluminium is pre-treated via SAT pre anodisation. Our factory in Powodowo is the only factory in Europe to offer this level craftsmanship, and one of only 5 facilities of its kind in the world.

Vacuum Impregnation

There are many ways to protect timber windows. But the single most important factor for longevity is thorough and robust impregnation of the timber that is used to make the window.

NorDan’s method of impregnation is the primary reason that our timber windows are provided with a 20 year warranty against rot and fungal infection. Our aluminium-clad timber products are provided with a 30 year warranty against rotting and fungal attack.

The timber window components are placed in a chamber that is filled with an impregnating liquid. The chamber is then pressurised to force the preservative liquid deep into the timber. After this process, the chamber is drained of fluid and placed under a high vacuum to remove any excess fluid.

The process used by NorDan complies with the requirements of BS 8417 ‘Preservation of Wood Code of Practice’, for a 60 year desired service life for external joinery components.

Surface penetration of 6mm in conjunction with a minimum 150mm of end-grain penetration provides a deep barrier of preservative treatment. Couple this with naturally impregnated heartwood from sustainable cold climate forests, and the result is a timber product that is guaranteed to perform for generations even in the harshest of weather conditions without yielding to rot and fungus.

Responsible Solutions

As part of our continued investment in sustainability through our ecoDigital Ready initiative (which takes a combined approach towards sustainability and digitalisation), NorDan UK has also established a dedicated Specification Team.

Establishing a dedicated team of technical specification advisors makes us stand out, offering a support for development and asset managers looking to optimise their specification. Our dedicated Specification Team allows us to understand the client and design requirements at an earlt stage.

Tom O’Sullivan (BA (Hons) Architecture) and John Williams, members of the NorDan Specification Team, are a driving force in the market with a clear goal to influence specification for a more sustainable future. To speak with Tom or John regards any queries relating to timber and our low carbon credentials, or to discuss your next project - please see details below:

Tom O’Sullivan

BA (Hons) Architecture

Technical Specification Advisor